Performance and Advantages of Nexthermal Coil Heaters

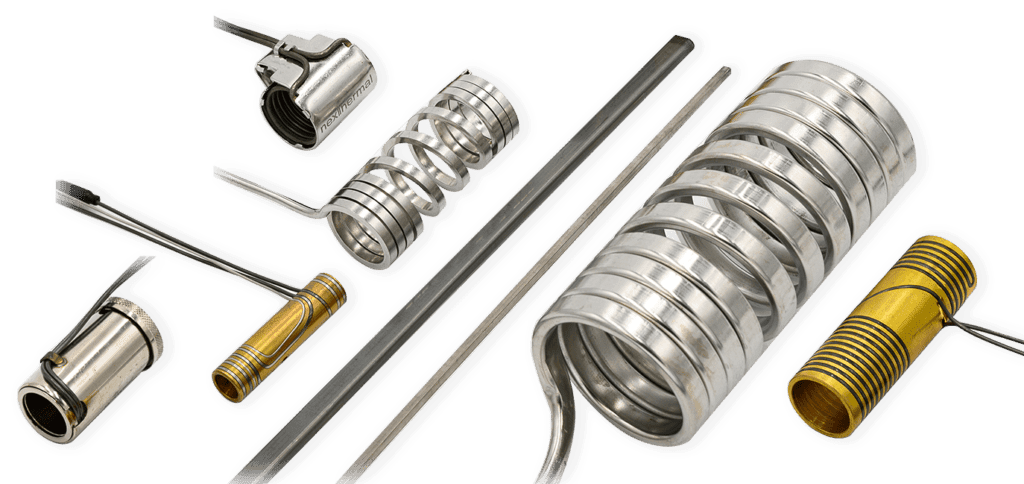

As an expert in thermal management solutions, I’ve seen the importance of heating coil technology in various industrial applications. Heating coils are a type of heating element used to transfer heat from one medium to another. They are used in various industries such as aerospace, automotive, medical, and semiconductor manufacturing. In this article, we’ll take a comprehensive look at Nexthermal’s efficient coil heaters and how they can benefit your business.

Understanding Coil Heater

A coil heater is a type of heating element that has a unique design that allows for high watt densities. It consists of a heating wire that is wrapped around a ceramic or quartz core. The wire is insulated to prevent short circuits and is then coated with a protective layer to prevent oxidation. The coil heater can be designed to fit any shape or size, making it an ideal solution for custom applications.

Types of Coil Heaters Available

There are various types of coil heaters available. Some of the most common types are:

Mini Coil Heaters

Mini coil heaters are small-sized heaters used in applications where space is limited. They have a small diameter and can be designed to fit any shape or size. They are commonly used in hot runner systems for injection molding.

Maxi Coil Heaters

Maxi coil heaters are used in applications where high watt densities are required. They have a larger diameter and can be designed to fit larger applications such as extrusion barrels and packaging machinery.

Micro Coil Heaters

Micro coil heaters are similar to mini coil heaters but are much smaller in size. They are commonly used in micro molding applications where precision and accuracy are critical.

Overview of Nexthermal’s Efficient Coil Heaters

Nexthermal is a leading manufacturer of coil heaters. Their coil heaters are designed to provide efficient and reliable heating solutions for various industrial applications. Nexthermal’s coil heaters are made with high-quality materials and are designed to withstand harsh environments. They offer a range of products to cater to different applications, including mini, maxi, and micro coil heaters.

Nexthermal’s coil heaters have a unique design that allows for high watt densities. They are made with high-quality materials such as nickel-chromium and are coated with a protective layer to prevent oxidation. They are also designed to provide even heat distribution, which ensures consistent heating across the entire surface area.

Benefits of Using Nexthermal’s Coil Heaters

There are several benefits of using Nexthermal’s coil heaters in your industrial applications. Some of the benefits include:

Energy Efficiency

Nexthermal’s coil heaters are designed to provide efficient heating solutions. They have a high heat transfer rate, which means that they can transfer heat quickly and efficiently. This results in lower energy consumption and reduced operating costs.

Durability

Nexthermal’s coil heaters are made with high-quality materials and are designed to withstand harsh environments. They can operate at high temperatures without losing their integrity, ensuring long-lasting performance.

Customization

Nexthermal’s coil heaters are designed to fit any shape or size. They can be customized to fit your specific application requirements, ensuring that you get the perfect heating solution for your needs.

Even Heat Distribution

Nexthermal’s coil heaters are designed to provide even heat distribution, which ensures consistent heating across the entire surface area. This eliminates hot spots and ensures that your application is heated uniformly.

Applications of Nexthermal’s Coil Heaters

Nexthermal’s coil heaters are used in various industrial applications. Some of the most common applications include:

Injection Molding

Nexthermal’s coil heaters are commonly used in hot runner systems for injection molding. They provide precise and accurate heating solutions, ensuring that the plastic material is heated evenly.

Packaging Machinery

Nexthermal’s coil heaters are used in packaging machinery to provide efficient heating solutions. They can be customized to fit any size or shape, ensuring that they fit perfectly in your application.

Semiconductor Manufacturing

Nexthermal’s coil heaters are used in semiconductor manufacturing to provide high-temperature heating solutions. They can operate at high temperatures without losing their integrity, ensuring that they provide reliable performance.

Conclusion: Benefits of Nexthermal’s Coil Heaters for Your Business

In conclusion, Nexthermal’s coil heaters are an ideal solution for various industrial applications. They provide efficient and reliable heating solutions that can help reduce operating costs and improve productivity. With a range of products to cater to different applications and customizations available, Nexthermal’s coil heaters are the perfect heating solution for your business. When selecting a coil heater, consider the watt density, operating temperature, and material to ensure that you get the perfect heating solution for your needs.