Why IR Heating is Ideal for Precise Packaging Applications

As electric vehicles (EVs) become more common, the need for reliable lithium-ion batteries continues to grow. One key part of battery production is pouch sealing. In this step, consistent and even heating is essential to make sure the battery is safe, long-lasting, and performs well.

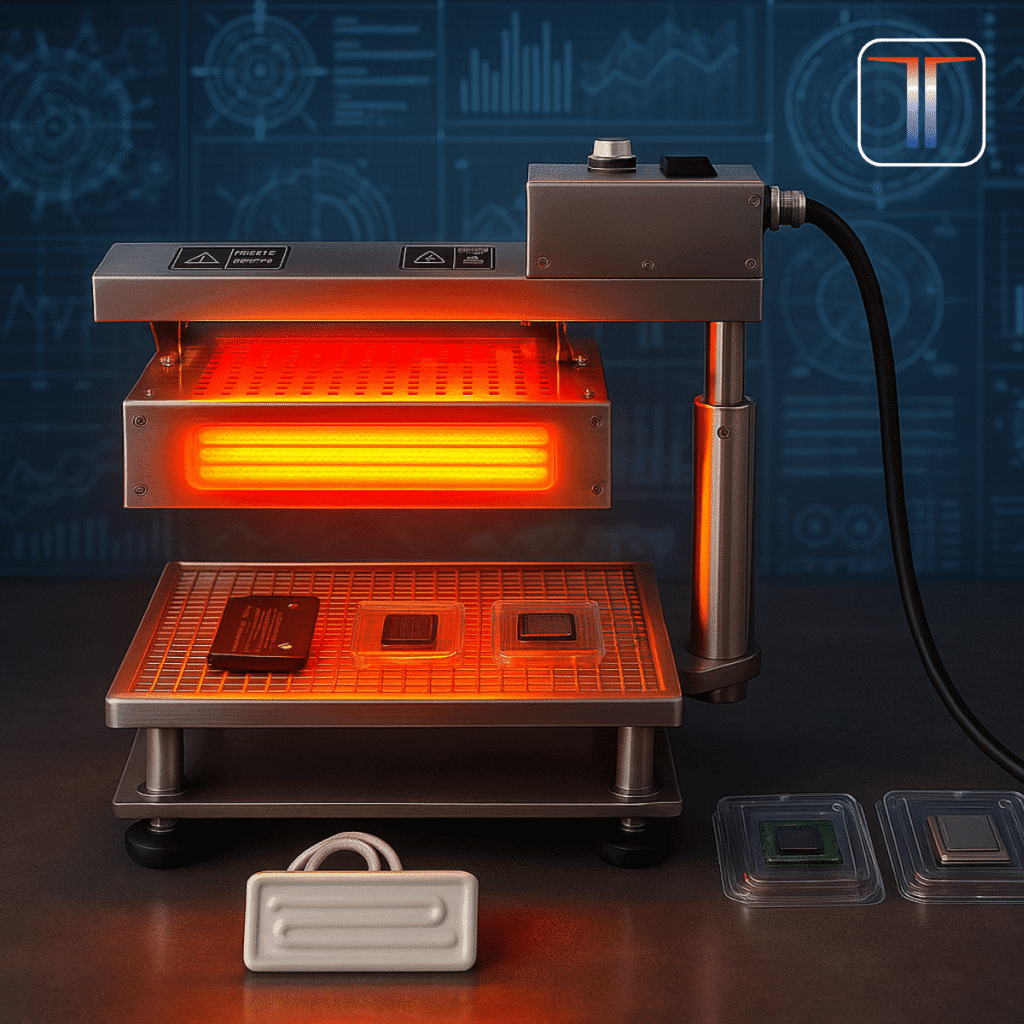

Ceramic infrared (IR) heaters are emerging as a superior heating solution for this process—offering unmatched speed, consistency, and energy efficiency. From battery sealing to blister packaging, ceramic IR technology is helping manufacturers streamline their production.

What Is Battery Pouch Sealing and Why It Matters

Battery pouch cells are enclosed in laminated aluminum foil, valued for their lightweight construction and energy density. However, sealing them requires:

- Airtight bonding to prevent electrolyte leakage

- Uniform heat application across laminated layers

- Controlled thermal exposure to protect battery chemistry

However, traditional methods like convection or conduction heating often struggle to provide consistent heat and can waste energy. Therefore, many manufacturers are turning to ceramic IR heaters as a more efficient and reliable solution.

Advantages of Ceramic IR Heaters in Battery Pouch Sealing

1. Uniform Surface Heating

Ceramic IR heaters emit radiation evenly across the sealing area, eliminating hot spots and ensuring consistent seals—critical for long-term battery safety and performance.

2. Fast Response Time

With rapid heat-up and cool-down capabilities, they support high-speed sealing lines without compromising on quality.

3. Non-Contact Heating

IR heating is contactless, reducing mechanical wear and contamination—ideal for delicate materials like battery pouch films.

4. Energy Efficiency

Unlike traditional methods, ceramic IR heaters direct heat precisely where needed, minimizing energy waste and aligning with sustainability goals.

5. Safe and Scalable

Ceramic elements are chemically inert and long-lasting, making them suitable for industrial EV battery manufacturing lines of all sizes.

Also Ideal for Blister Packaging Applications

In addition to battery production, ceramic IR heaters are also used in blister packaging. This method is common in industries like pharmaceuticals, electronics, and consumer products. As a result, these heaters help improve both product safety and packaging speed.

In this application, plastic films (like PVC or PET) are heated and formed into cavities for product containment. Ceramic IR technology enables:

- Consistent film heating for clean, accurate thermoforming

- Faster cycle times and less downtime

- Compact designs suitable for modern packaging machines

Nexthermal’s solutions are commonly used in industries requiring precision forming and energy efficiency, such as vacuum forming , blister packaging & other. Explore our applications.

Real-World Use in EV Manufacturing

According to AZoM, industry leaders are already integrating infrared heating into processes like pouch sealing, tab drying, and electrolyte filling. Ceramic IR heaters offer process control and flexibility that conventional methods can’t match.

Nexthermal provides advanced ceramic IR heating systems that fit seamlessly into automated EV battery production and advanced packaging systems.

Why Nexthermal?

At Nexthermal, we specialize in custom-engineered heating solutions for industries that demand accuracy, consistency, and energy savings.

Benefits of working with us include:

- Application-specific heater designs

- Lower energy consumption and maintenance costs

- Expert integration support for battery and packaging lines

Whether you’re producing EV batteries or blister packaging products, we help you elevate your thermal performance.

Ready to Seal the Future?

Your sealing process deserves the best in heating technology. Nexthermal offers tailored ceramic IR heating systems to improve efficiency, quality, and throughput.

Contact us today for a consultation, or browse our complete range of solutions.

Let Nexthermal power your precision.